In the realm of sustainable innovation, pyrolysis plant cost has emerged as a pivotal factor, influencing the viability of waste-to-energy solutions. This transformative technology harnesses the power of heat and chemistry to convert various organic materials, such as plastics, tires, and biomass, into valuable products like biofuels, carbon black, and syngas. However, for many potential investors and entrepreneurs, the enigmatic world of pyrolysis plant cost often seems like a perplexing maze.

Defining the Pyrolysis Puzzle

Before delving into the intricacies of pyrolysis plant cost, it’s essential to understand the heart of this matter: pyrolysis itself. Pyrolysis is a thermal decomposition process where organic materials are subjected to high temperatures in an oxygen-deprived environment. This results in the breakdown of complex molecules into simpler compounds, leading to the creation of valuable resources while minimizing waste.

The Significance of Pyrolysis Plants

The drive towards sustainability and eco-consciousness has fueled the relevance of pyrolysis plants. These facilities play a pivotal role in solving environmental issues by transforming waste materials into profitable products. By reducing the burden on landfills and incineration, pyrolysis plants contribute to a more sustainable future.

Cracking the Code of Pyrolysis Plant Cost

Understanding the cost of pyrolysis plants is akin to deciphering a complex code. Several factors influence this equation, making it a multifaceted challenge:

1. Technology and Design

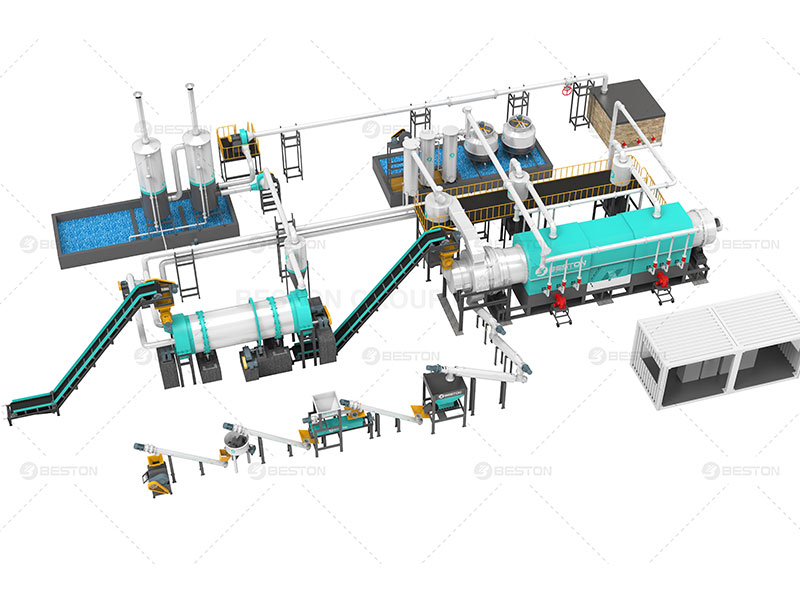

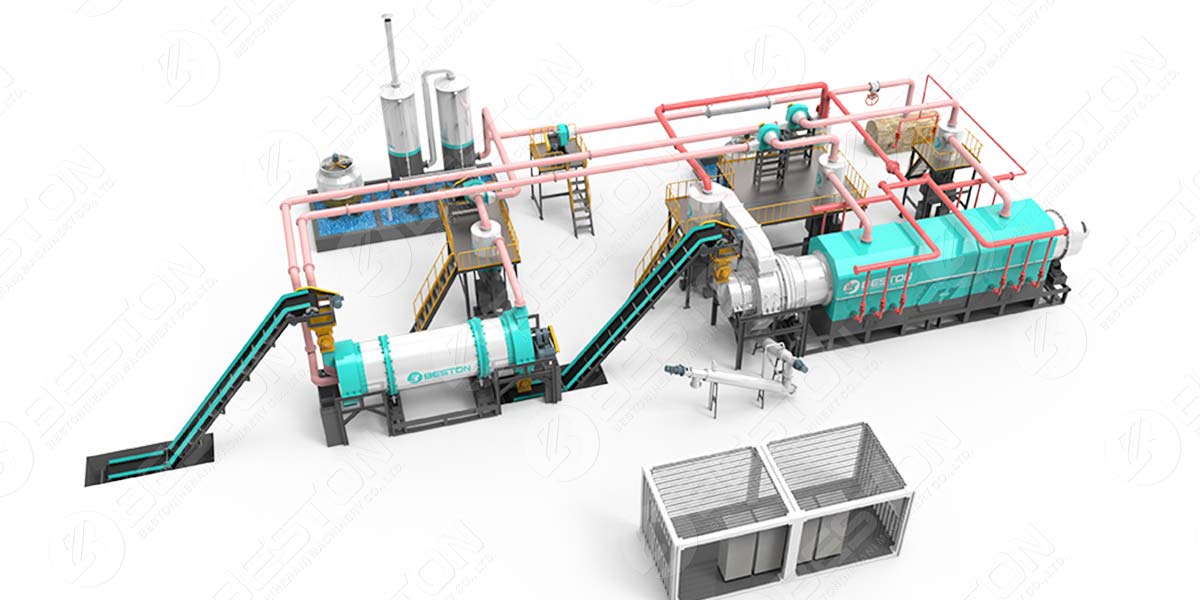

The choice of pyrolysis technology and plant design is a primary factor impacting costs. Advanced, state-of-the-art technologies may come with a higher initial investment, but they often yield better efficiency and product quality in the long run.

2. Capacity and Throughput

The size and capacity of a pyrolysis plant are key drivers of cost. Larger facilities can process more feedstock, but they necessitate a higher upfront investment.

3. Feedstock Variety

The type and source of feedstock significantly influence the cost of the pyrolysis process. Some materials require more extensive pre-processing, which can add to the expenses.

4. Environmental Regulations

Adhering to stringent environmental regulations is non-negotiable. Compliance often entails additional costs for emission control and waste management systems.

5. Geographic Location

The plant’s geographic location also plays a part. Regional factors, including labor costs, access to feedstock, and local regulations, can all impact the overall cost.

6. Market Competition

In regions with a proliferation of pyrolysis plants, market competition can result in cost optimization through technological advancements and efficient operations.

Breaking Down the Pyrolysis Plant Costs

Understanding the intricacies of pyrolysis plant cost requires a comprehensive view of the expenses involved. Let’s break it down:

A. Initial Investment

- Equipment and Machinery: The heart of any pyrolysis plant, the plastic pyrolysis plant, can range from basic to highly sophisticated, affecting the initial capital investment.

- Land and Infrastructure: Securing the right location and building the necessary infrastructure can constitute a significant portion of the expenses.

- Permits and Licensing: Compliance with local regulations and acquiring the necessary permits is a vital, albeit often underestimated, aspect of the initial investment.

B. Operational Costs

- Labor and Maintenance: Skilled labor and regular maintenance are essential for efficient operation but also contribute to ongoing expenses.

- Energy and Utilities: Energy consumption, such as electricity and heat, forms a substantial part of the operational cost.

- Feedstock Acquisition: The cost and availability of feedstock, such as plastic waste or tires, directly impact operational expenses.

C. Regulatory Compliance

- Emissions Control: Implementing emission control systems, like scrubbers and filters, ensures compliance with environmental regulations but also adds to costs.

- Waste Management: Handling the byproducts and waste materials generated during pyrolysis necessitates proper waste management processes.

- Safety Measures: Ensuring a safe working environment involves expenses related to safety equipment, training, and protocols.

Strategies for Cost Optimization

Minimizing pyrolysis plant cost is a goal for both environmental sustainability and economic viability. Here are some strategies to achieve that:

A. Efficient Plant Design

Investing in well-designed, efficient systems can enhance overall productivity, reduce energy consumption, and, ultimately, decrease costs.

B. Proper Maintenance and Monitoring

Regular maintenance and rigorous monitoring of equipment ensure longevity, prevent downtime, and reduce the overall cost of operations.

C. Sustainable Feedstock Sourcing

Exploring eco-friendly sources of feedstock or partnering with organizations that provide waste materials at a lower cost can be a game-changer.

D. Recycling Byproducts

Finding innovative ways to utilize byproducts, such as turning char into activated carbon or utilizing syngas, can generate additional revenue streams and offset costs.

E. Government Incentives

Many governments offer incentives and subsidies to encourage the development of pyrolysis plants. These can significantly reduce initial investments and ongoing operational expenses. More information from Beston Group.

The Road Ahead

Navigating the pyrolysis plant cost landscape may be complex, but it’s a journey worth embarking on. As environmental concerns intensify and waste challenges mount, the potential for sustainable, cost-effective solutions becomes increasingly vital. Understanding the factors at play and employing cost-saving strategies can pave the way for a future where pyrolysis plants play a crucial role in waste management and sustainable resource production.