How much do you know about machines used to make charcoal from coconut shells? What do you understand about this business? Do you know it is an extremely popular business when set up in the right manner?

Charcoal is always in high demand as it is increasingly being used in a wide range of industries including pharmaceutical industry, skincare products, food industry and in many other ways. In short, there is a high demand for good quality charcoal but making good quality charcoal isn’t as easy as burning off biomass.

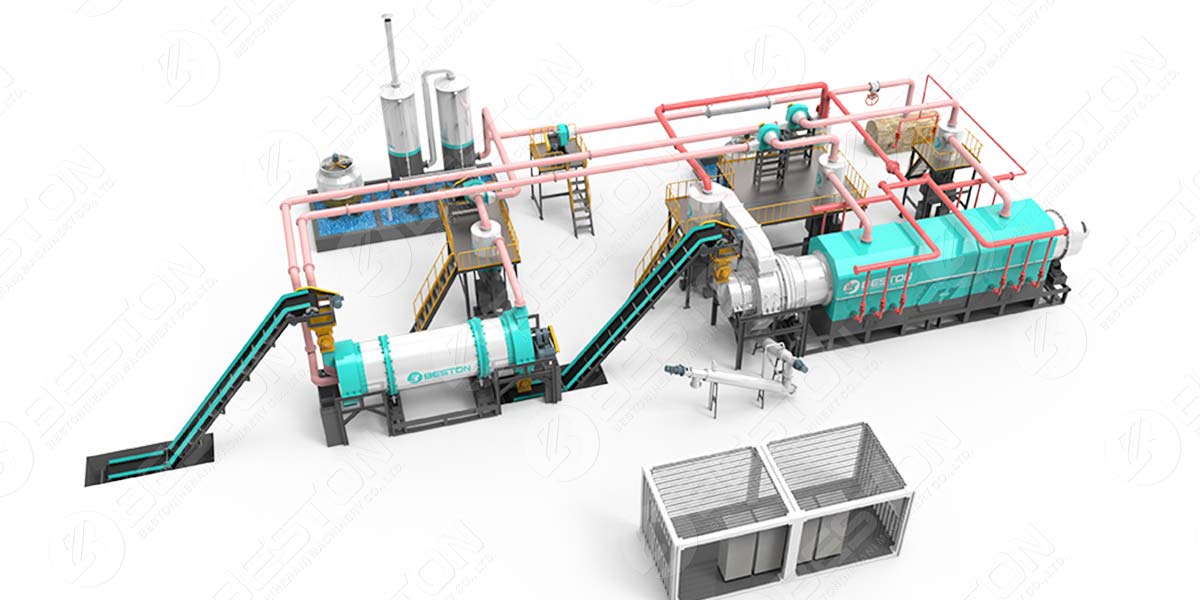

Making charcoal and making high-quality charcoal are different things. The raw material needs to be dry enough to ensure moisture content below 10% and then, the carbonization process needs to be carried out in the right manner to ensure formation of good quality and energy dense charcoal. The only way this can be done on a consistent basis is with the help of a high-quality coconut shell charcoal making machine.

Charcoal machines are widely available and you might think that you can buy any machine and expect great results. Unfortunately, that’s not how it works in the real world. Due to the huge demand for these machines, several companies have jumped in this industry and started manufacturing these machines without any real expertise.

They often use poor quality materials and old designs to cut corners as the only thing they have going for them is lower prices. In short, you can’t buy a machine from anywhere and expect to operate a profitable business. You have to do your own research to choose the right machine. Here is a brief list of the factors that matter:

- Adequate processing capacity

- Batch or continuous operation

- Level of automation

- Flexibility in fuel use

- Approximate yield

- Manufacturer’s reputation

Make sure you choose adequate processing capacity which is neither too low nor too high. Do not choose a capacity based on your gut instinct. Do market research to find out the demand for charcoal in your location and only then you should place an order for a particular processing capacity. More information on charcoal making machine here.

Automation helps in cutting down costs in the long run but you have to pay for the automation. If you don’t have any problem in finding workers at reasonable costs, you shouldn’t have too many problems running a semiautomated plant profitably. However, fully automated plants not only save money on labor costs but also ensure 100% accuracy.

Some of these machines/plants offer a wide range of flexibility when it comes to fuel types. Depending on the prices of different fuels, you might prefer one fuel type over another. This is why it’s important to invest in a biomass pyrolysis plant with flexibility in type of fuel that can be used for the carbonization chamber.

Manufacturer’s reputation is also important as it immensely affects the quality of the plant, its durability, reliability and availability of replacement parts. You wouldn’t want to end up in a situation where you are unable to find replacement parts or technicians for servicing & maintenance.

Overall, a coconut shell charcoal making machine is usually a profitable investment but only when you choose the right machine and have a proper business plan. Make sure you pay attention to the above discussed factors to set up a strong foundation for your charcoal making and selling business. See the sawdust charcoal making machine here.