In the realm of sustainable solutions and eco-friendly ventures, the establishment of a tyre pyrolysis plant stands out as a pioneering initiative. This cutting-edge technology not only addresses the burgeoning issue of tire disposal but also taps into the lucrative realm of recycling. However, diving into the world of tyre pyrolysis demands a thorough understanding of the labyrinthine regulatory landscape, as compliance is key to a seamless launch.

Environmental Clearance: Paving the Green Path

Initiating a waste tyre pyrolysis plant necessitates obtaining environmental clearances, a foundational step ensuring adherence to stringent ecological standards. This approval is granted by environmental authorities after a meticulous evaluation of the plant’s potential impact on the surrounding ecosystem. The objective is to ascertain that the proposed venture aligns with sustainable practices and poses no threat to the environment.

Consent to Establish and Operate: The Operational Green Light

Once the environmental clearance is secured, the next crucial step involves obtaining the “Consent to Establish” and subsequently, the “Consent to Operate” from the State Pollution Control Board. These consents signify regulatory approval for the plant’s construction and operation phases, respectively. Meeting emission standards and waste disposal guidelines are imperative components of the approval process, emphasizing the commitment to environmental responsibility.

Hazardous Waste Authorization: Managing Byproducts with Precision

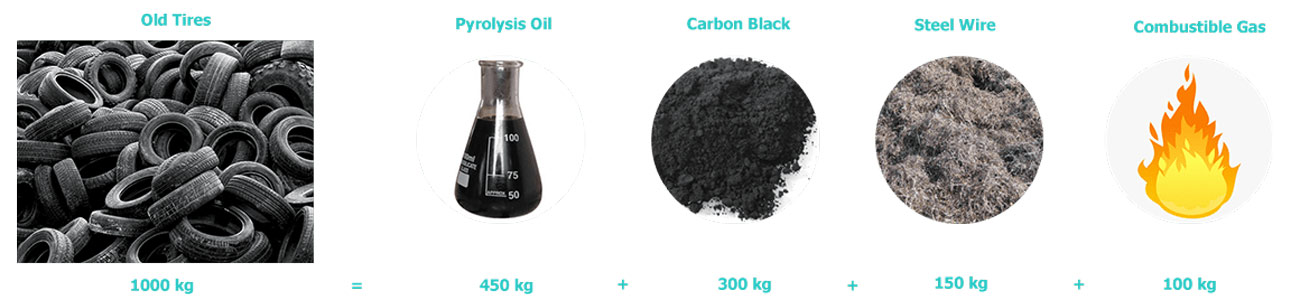

Given the nature of tyre pyrolysis, where the process yields byproducts that fall under the category of hazardous waste, obtaining Hazardous Waste Authorization is imperative. This authorization ensures that the handling, storage, and disposal of the hazardous byproducts are executed with precision and compliance. Stringent measures are in place to safeguard against any adverse impact on human health and the environment.

Fire Safety Approval: Navigating Potential Risks

Acknowledging the inherent risks associated with the tyre pyrolysis process, securing fire safety approvals is paramount. This involves a comprehensive evaluation of the plant’s fire safety measures, emergency response plans, and containment protocols. Compliance with fire safety standards not only mitigates potential risks but also demonstrates a commitment to the safety of personnel and surrounding areas.

Air and Water Pollution Control: A Dual Regulatory Embrace

To ensure the tyre pyrolysis plant‘s operations do not contribute to air or water pollution, obtaining approvals from the respective regulatory bodies is imperative. Stringent monitoring of emissions and effluents, coupled with the implementation of advanced pollution control technologies, are essential components. This dual regulatory embrace underscores the commitment to maintaining air and water quality standards.

Customs and Excise Duty: Navigating Fiscal Regulations

Beyond environmental considerations, delving into the regulatory realm involves navigating fiscal landscapes. Securing necessary customs and excise duty clearances ensures adherence to tax and duty obligations associated with importing machinery and raw materials. A thorough understanding of fiscal regulations is pivotal for a seamless and compliant operation.

Boiler Operation Approval: Sustaining Energy Requirements

The tyre pyrolysis process often involves the use of boilers to generate energy. Obtaining boiler operation approvals is critical to ensure the safe and efficient utilization of this energy source. Compliance with boiler operation standards not only ensures operational safety but also contributes to the sustainable energy footprint of the plant.

Waste Management Authorization: Closing the Loop

An integral facet of tyre pyrolysis is efficient waste management. Acquiring waste management authorization is imperative for the systematic handling, treatment, and disposal of residues generated during the process. This authorization ensures alignment with waste management protocols, emphasizing a closed-loop and environmentally conscious approach.

Conclusion: Navigating Compliance for a Sustainable Future

Whether it is a tire, sludge or plastic pyrolysis plant, it needs to go through the meticulous dance of regulatory circles. From environmental clearances to fiscal obligations, each approval serves as a cornerstone for a sustainable and compliant operation. As the demand for eco-friendly solutions intensifies, navigating the regulatory landscape with finesse becomes not just a necessity but a testament to a commitment to a greener and more sustainable future.