The use of pyrolysis technology has become a worldwide phenomenon. It is due to the improvements that have been made when using these devices which can convert waste material into usable fuels. It is possible to take rubber tires or plastic bottles and convert those into different types of fuel, or carbon black. As they have been improved over the years, you can clearly see that this is a very lucrative business, especially if you have a consistent supply of recyclable materials that can be converted in this manner. This is the most commonly used pyrolysis plant design that you will find when shopping around for one of these unique plants for your business.

What The Pyrolysis Process Does

This process involves the use of a substantial amount of heat. However, it is in the absence of burning. When these products are created, they are the result of breaking down the structure of the initial materials. For example, when you place a large amount of plastic into a pyrolysis chamber, it will be sealed off, eliminating the possibility of combustion. Once the air is removed, the temperature will rise inside, and that material will begin to break down.

How Are Pyrolysis Plants Designed?

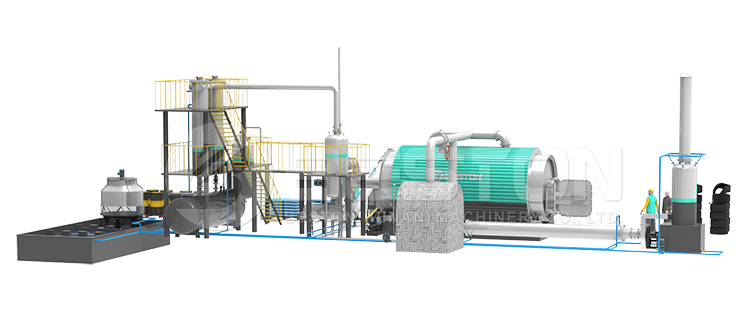

These are designed in a very similar manner, regardless of where you get one from. For example, they will start with a conveyor belt that will deliver the material to a pyrolysis furnace. Also, you can feed manually. Inside, the material will be placed, a chamber that will be devoid of air. Temperatures will rise inside, and will quickly be broken down into solids, liquids, and gas. The gas will solidify into a liquid which will be bio oil or biofuel. The solid portion will be carbon black that is the byproduct of these materials going through this procedure.

Can They Be Designed In Different Sizes?

There are many different sizes that you can get these in. For example, the most common ones are quite small. These are for small to medium-sized businesses that may have extra plastic and rubber that needs to be processed. However, these can be designed to be the size of a large plant, capable of processing thousands of tons of material. These are ideal for landfills that may almost exclusively have plastic bottles or rubber tires. The rubber pyrolysis plant design that you choose should be representative of how much material you process daily. You may already have a small pyrolysis plant that you are using, but you know that it is taking too long to process everything. That’s why expanding your operations and having one brought in that is larger will be a good decision.

The pyrolysis plant design that you choose should be one that is not just affordable but is likely going to be the most efficient pyrolysis plant you have ever owned. It is also a good idea to shop around to choose one that is affordable. These may come from overseas businesses that are already well-known for producing the best ones in this industry. Here is a website for your reference: https://bestonasia.com/tire-pyrolysis-plant-cost/.