When you’re investing in a tire recycling plant, it’s easy for essential expenses to be overlooked. You’ll want to make sure you’re prepared for all of the costs that you have to cover. That way, you’ll be able to make sure you select machinery that is within your budget. Below is what the tyre recycling plant cost covers.

Shipping Costs

If you choose to have equipment shipped out to you, you may be responsible for shipping costs. These costs can be quite high and can wind up inflating the total cost of your purchase. You’ll want to make sure that you know what shipping is going to cost you ahead of time. The total cost of shipping can vary from one vendor to the next, which is why it’s smart to compare shipping rates before you make a purchase. You may find that you’ll get a better deal if you buy your plant from a particular vendor, even if the cost of a particular piece of machinery is higher.

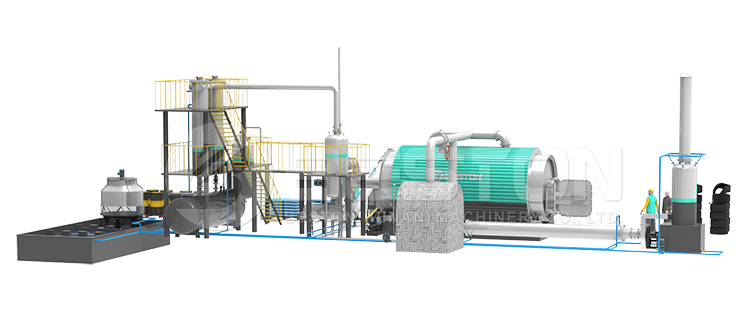

Pyrolysis Machine Cost

The main part of the tyre recycling plant cost is the pyrolysis machine price. It often differs from the capacity, working method, etc. Also, it will influence the other part, such as the space you need, the labor force, etc. More models of pyrolysis machine for sale can be found: https://wasterecyclingplant.com/waste-pyrolysis-plant/.

Operating Costs

One of your biggest expenses you’ll have to cover is the cost of utilities. Machinery like this can consume a lot of power, even you invest in equipment that’s energy-efficient. Energy-efficient equipment can lower your costs over time, which is why it often makes sense to purchase machinery that doesn’t consume as much power. It’s a good idea to estimate what your monthly utility costs are likely to be so that you’ll be able to cover this bill without any issues.

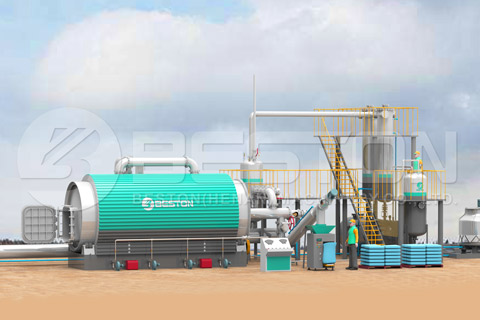

Maintenance Costs

As mentioned, the pyrolysis equipment you’ll need to recycle tires can be a major investment, which is why you’ll want to do everything you can to keep that equipment in good working order. You’ll want to make sure that your equipment is inspected regularly so that you can quickly apply repairs as needed. If parts are damaged, you’ll want to repair them with new parts. You’ll also want to make sure your machinery is lubricated regularly. You should make sure you choose the right kind of lubricant for the machinery that you’re using. It’s a good idea to read the manual for your equipment so that you can see what it needs. Below is an upgrading system for tyre recycling plant in India.

Labor Costs

A lot of the machinery you’ll buy for your tyre recycling plant will be able to operate on its own. With that said, you’ll still need to have some people working in the plant. You’ll want to determine how many workers you’ll need to hire and what their qualifications will need to be. If your plant is appropriately staffed, it’s likely that you’ll have fewer problems with your machinery. You should make sure that you can afford to pay the workers that you need. If you take this expense into account when you’re setting your budget, this expense will be easier for you to afford.

Make sure you look at all tire recycling plant costs before you make any sort of commitment. Add up all of the potential costs and look at your potential income from your plant. That way, you can make an informed decision about what you want to spend. If you want a customized tyre recycling plant business plan, contact Beston Machinery for help.