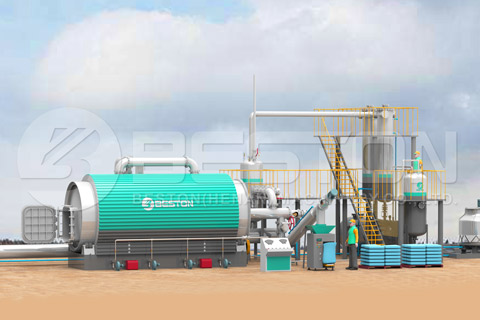

Biochar production equipment involves the carbonization of the biomass materials into charcoals through the various reactions that occur in a series. It is the machine that can be referred to as biomass carbonization machine or biochar pyrolysis equipment. The machine has employed advanced technology through high temperatures. This device is well equipped with the aim of making charcoal and ensuring that the waste biomass is bought into use by producing energy. The machine is widely used in various countries like Ukraine, South Africa, Austria among other countries.

The main materials that are used in the process come from the biomass that can include, wood, rice husk, coconut shell, sawdust among other materials that are usually readily available. The final product from the Biochar provides more energy, can burn for a long period, does not emit smoke to the environment among others are some of their characteristics. The charcoal can too be used in industrial smelting, warming and cooking in homes. The biochar production equipment for sale does not only deal with the waste materials alone but can make their customers have a profit at the same time preserving the environment.

The production

The machine is made in a way that it incorporates both pyrolysis technology and advanced technology. These technologies are able to convert the waste into charcoal through the various processes of crushing, drying, and carbonization process, cooling and discharging of the end products. The end products from the process are at high demand in the market because they can be used both at home and industries. In addition to that some of the Biochar charcoal has been transported to various countries which have not bought the BBQ charcoal machine.

End products produced by Biochar making the machine

The biomass charcoal- this is the main product that can be used as fuels in various industries in smelting. The charcoal also produces energy of high quality and hence can be used at home for domestic purposes. The charcoal is rich in micro-element like calcium, phosphorous, nitrogen among others and hence it can be used as a fertilizer in order to improve the soil quality and hence high yields.

Tar

This material contains more than 300 various chemical elements that are crucial. One of the uses of tar is that it can be used to make waterproof materials and paints. It can also be used in the field of medicine.

Wood vinegar

This is another end product from the biochar machines for sale. The product can be used as a food preservative and too can be applied in the field of medicine.

Advanced and superior Biochar production

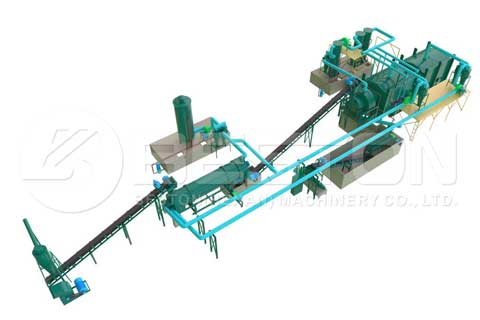

The whole process of Biochar pyrolysis can be divided into 4 main parts where various processes take place. The four parts include the pre-treatment of the biomass, carbonization, the smoke discharge, emission of sulfur and charcoal enrichment. The whole process is secure and efficient in how it works.

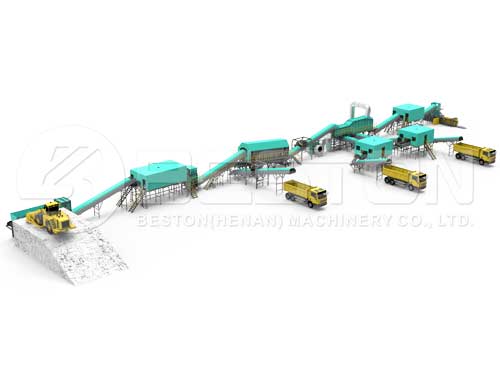

First, the biomass materials are crushed into small pieces of around 50mm. the crushed are then dried in the dryer device in order to remove the moisture from it. The temperature is maintained to ensure that around 20% of moisture has been removed.

Then the biomass is totally heated at the Biochar in order to make the furnace.

During the heating process, the smoke that is produced is piped to the purification chamber in order to remove sulfur from it. It later transferred to the carbonizing furnace or to the dryer to provide more energy to the system.

The biomass charcoal can then be discharged when the product has been cooled down in the cooling sector. In the process, combustible gas is emitted in the biochar reactor. The gas can be condensed back to tar or wood vinegar.

You can click here to learn more detailed information about the working process of biochar production: https://www.bestongroup.com/wood-charcoal-making-machine/.

An important requirement for Biochar charcoal production

·The raw materials must be crushed into small pieces of around 20mm before they are heated.

·The moisture of the biomass material should be below 50% in order to yield more charcoal output.

·For maximum production, the fuel must be heated for around 30 minutes and you can recycle the gas produced in the biochar.

reactor to achieve this.

Advantages of Biochar machine

·It uses free and common materials that have been thrown in the environment to turn them into useful products within the society. To add on that the process is environmentally friendly.

· The machine is able to customize and satisfy the needs of the customers. For instance, without a case, we are able to promote high capacity production.

Contact Beston Company and there will be professional sales consultant answer all your questions about the biochar machines.