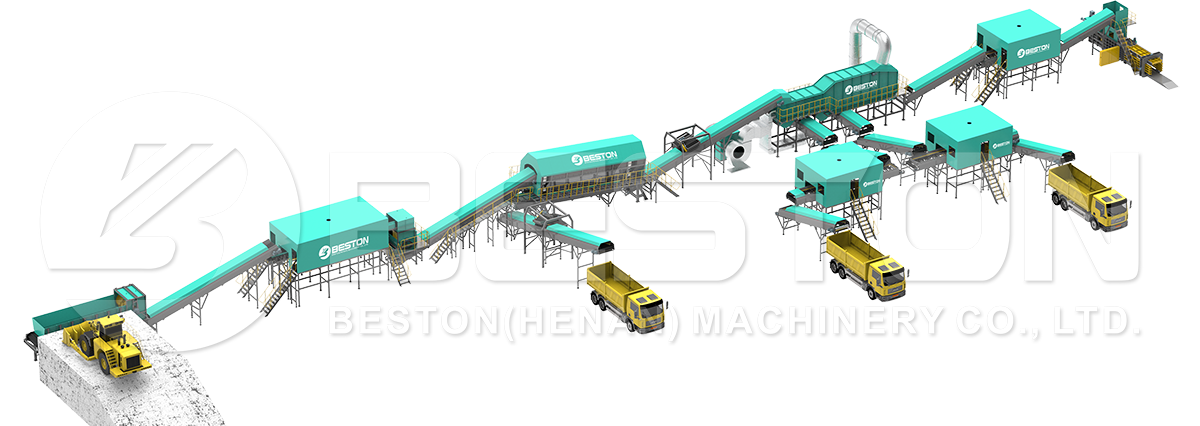

The tyre to oil plant is an appliance that converts rubber, waste tires, and other waste materials into carbon black, pyrolysis oil and hydrocarbon gas. By using this waste to tire pyrolysis plant, you can minimize the volumes of the waste products and even assist in protecting the environment. The process of turning the waste tires into useful fuel oil is referred to as tire pyrolysis. During the production of tires, the most popularly used synthetic polymer is butadiene copolymer. The end product of tire pyrolysis and waste plastic is pyrolysis oil. Pyrolysis oil is mostly used as industrial fuel to serve as an alternative for industrial diesel or furnace oil.

Reasons to Acquire a Tire to Oil Plant

If you have never considered buying one, or even heard about one this is undoubtedly a thing that you ought to have. If you run a business that has abundant availability of rubber tires, then this might be a secondary business that would be more suitable for your company. It can actually be a valuable asset to your business to have the skill to convert these tires into sell-able bio-fuel. For this reason, you should consider acquiring a pyrolysis plant that can create oil from rubber tires.

Waste tyre pyrolysis plant helps to alleviate the problem of rubber tires, which end up being placed into landfills. What’s more, breaking down tires can result in a wide variety of products that you can use or sell. After the process, you’ll end up getting bio-fuel for diesel engines, charcoal, and even the bio-fuel, which is mostly available in many different ways.

The industrial sector will most likely be looking for this type of fuel to act as a lubricant substitute to replace the costly oil they use with their machines. Also, the cosmetic sector is always trying to seek various reliable sources for fuel to make use of in their particular cosmetic products.

Benefits of Acquiring a Tire to Oil Plant

Acquiring this plant will surely be lucrative for nearly any business. You’ll incur a substantial initial investment, but you’ll certainly be paid back within a few years. Although your primary objective would be to break down waste materials into oil, you’ll still require the other byproducts since you can sell them. For people who’re responsible for a specific landfill that’s stuffed with large amounts of rubber tires, this may be your solution for increasing the revenue of your particular business.

Tips for Choosing the Right Tire to Oil Plant

It will only take you a couple of days of research to acquire the most suitable tire to oil plant for your company. You’ll have to consider all the available possibilities. For those who are considering to purchase one superb pyrolysis plant to turn their rubber tires into useful and sell-able oil, there’s a business out there that can offer you a great deal to use one.

Make sure that your choice of pyrolysis plant is calibrated for turning rubber tires into any of the byproducts, at a reasonable price. Apart from checking out online advertisements, you should spend some time doing the investigation.