Investing in an egg tray manufacturing machine can help you produce a wide range of paper products including egg trays, fruit trays and a few dozen other types of products. There are manual, semiautomatic and fully automatic configurations but in this article, we are going to discuss the many advantages of a fully automated machine. Here’s why you should try to buy a fully automated machine:

Extremely Fast Production Rate

One of the biggest advantages of investing in a fully automated egg tray manufacturing machine is that it is capable of producing thousands of products per hour. Manual or semiautomatic machines cannot even come close to the production rate of this machine. If you are already in this business and want to take your business to the next level, there is nothing better than a fully automated production line to achieve that goal.

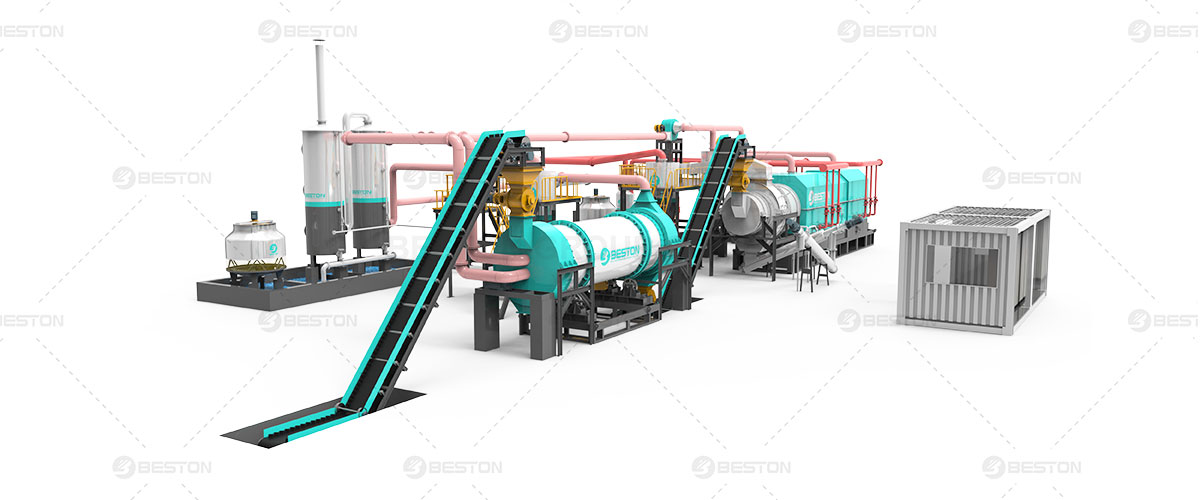

One of the main differences between a fully automated production line and other configurations is that it includes everything needed to produce a final product. For instance, this product line involves includes the pulping, molding as well as the drying system. In case of semiautomated or manual machines, the drying takes a lot of time. On the other hand, drying is fully automated which helps in taking the production rate to the next level.

Fewer Errors

A fully automated egg tray making machine also means fewer errors as there is minimal human intervention required in the manufacturing process. Almost all the parts of the process are fully automated. It results in much higher accuracy as compared to alternatives. Needless to say, it also ensures much more consistency in the final product.

More Efficient

Fully automated production lines are also much more efficient as compared to alternatives in terms of fuel efficiency, production efficiency and overall workflow efficiency.

Buying the Right Machine

As we have discussed, there are several advantages of a fully automated egg carton machine but you’re going to realize those benefits only if you buy the right machine. There are thousands of brands of these machines. You would be able to find at least a few dozen in your own country. If you start searching globally, you will be able to find thousands more.

Don’t make the mistake of assuming that every manufacturer out there is capable of designing and manufacturing a high quality machine. In fact, many manufacturers cut corners in terms of variety of materials and quality of components to bring down the price and gain market share. You should stay away from such manufacturers.

When comparing manufacturers, your focus shouldn’t be on the initial price only. Find out the number of years the company has been in business. Check their customer reviews on trade portals and groups on social media. Become part of online communities related to this business and ask other users about their experience of dealing with the company you are considering. In short, you need to do your research to ensure that you’re dealing with the right company.

Overall, there are several advantages of a fully automated pulp moulding machine but it is important for you to choose the right manufacturer. Don’t focus on price alone. Focus on quality of the product and it will help you set up a strong foundation for your business.