Charcoal production is becoming an increasingly popular and sustainable solution for waste management and energy needs. This process involves converting various types of biomass into charcoal, which can be used as a fuel source, soil amendment, and more.

Bamboo Charcoal Machine: A Sustainable Solution

A bamboo charcoal machine is an innovative piece of equipment designed to convert bamboo into high-quality charcoal. Bamboo is a fast-growing plant, making it an excellent raw material for charcoal production. This machine uses a carbonization process to convert bamboo into charcoal, with minimal environmental impact.

The bamboo charcoal machine operates by heating the bamboo in an oxygen-free environment, which prevents it from burning and allows it to decompose slowly. As a result, the bamboo is transformed into charcoal, a process that is efficient, eco-friendly, and sustainable. The bamboo charcoal produced is rich in carbon and has a high calorific value, making it ideal for various uses, including heating and cooking.

Palm Kernel Shell Charcoal Making Machine: Utilizing Agricultural Waste

The palm kernel shell charcoal making machine is another efficient machine used in charcoal production. This equipment is specifically designed to convert palm kernel shells, a common byproduct of the palm oil industry, into valuable charcoal. The process not only helps in managing agricultural waste but also produces high-quality charcoal with excellent energy content.

The palm kernel shell charcoal making machine works by heating the shells in a controlled, oxygen-free environment. This carbonization process results in the conversion of palm kernel shells into charcoal, which can be used as a fuel or as an activated carbon product for water purification and other industrial applications. Manufacturers can efficiently turn waste into a profitable product by utilizing the palm kernel shell charcoal making machine while promoting sustainable practices.

Sludge Treatment Plant: Turning Waste into Resources

A sludge treatment plant is typically used in waste management facilities to process sludge, which is a byproduct of sewage treatment. However, it can also be employed in charcoal production to convert organic sludge into charcoal. This innovative approach transforms waste materials that would otherwise contribute to environmental pollution into useful resources.

The sludge treatment plant operates by removing excess water from the sludge and then carbonizing the remaining organic material at high temperatures. This process results in the production of biochar, a form of charcoal that can be used in agriculture to improve soil health, reduce greenhouse gas emissions, and promote sustainable farming practices. Incorporating charcoal production into sludge treatment offers a dual benefit of waste management and resource recovery.

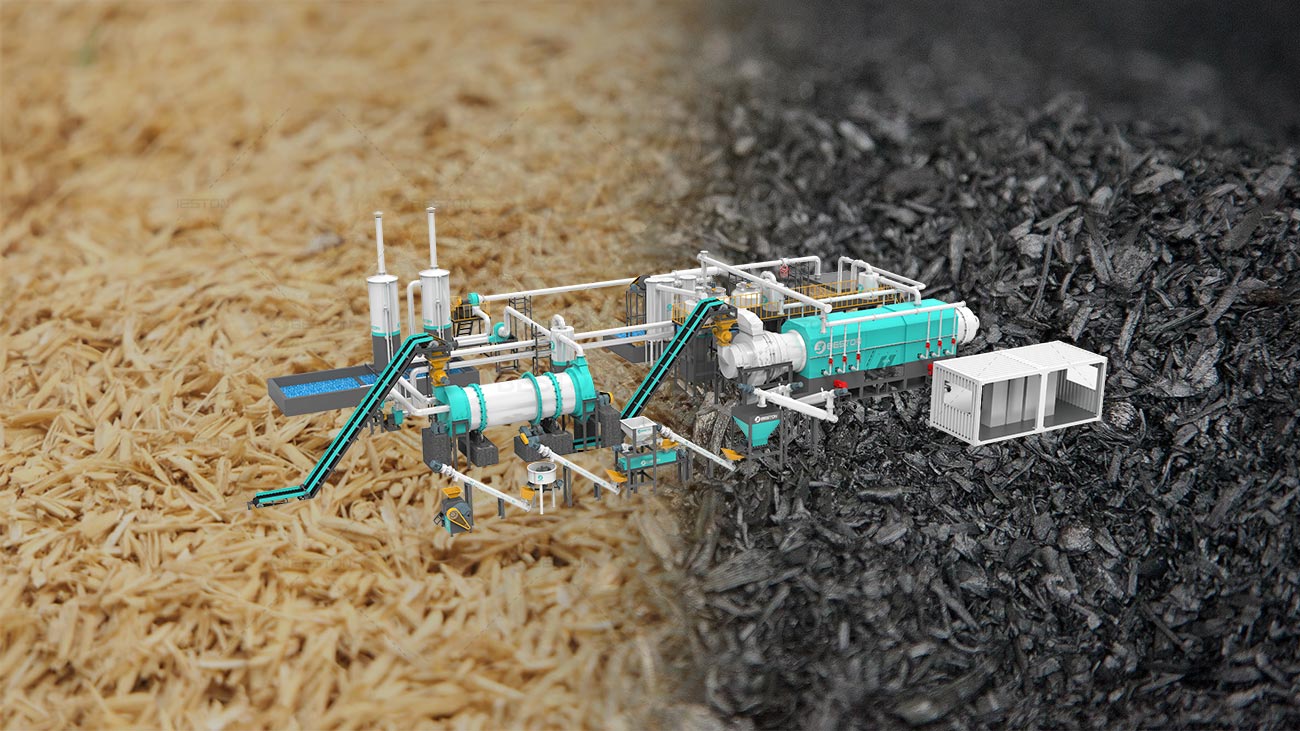

How to Make Charcoal from Sawdust: A Practical Approach

Understanding how to make charcoal from sawdust is essential for maximizing the use of available resources. Sawdust, often considered a waste product in the woodworking industry, can be effectively turned into charcoal. The process is both economical and environmentally friendly, reducing waste and producing a high-energy fuel source.

To learn how to make charcoal from sawdust, the sawdust must first be dried to reduce its moisture content. It is then subjected to a process called pyrolysis, where it is heated in an oxygen-free environment. This process breaks down the cellulose in the sawdust and converts it into carbon-rich charcoal. The resulting product can be used in various applications, including heating, cooking, and even as a raw material for activated carbon production.

Conclusion

Charcoal production is an innovative and sustainable method of managing waste and producing valuable resources. By utilizing equipment like the bamboo charcoal machine, the palm kernel shell charcoal making machine, and integrating the processes in a sludge treatment plant, we can turn waste into wealth. Additionally, understanding how to make charcoal from sawdust offers a practical approach to using wood waste efficiently. These methods and technologies demonstrate how modern techniques can contribute to a more sustainable and environmentally friendly future.