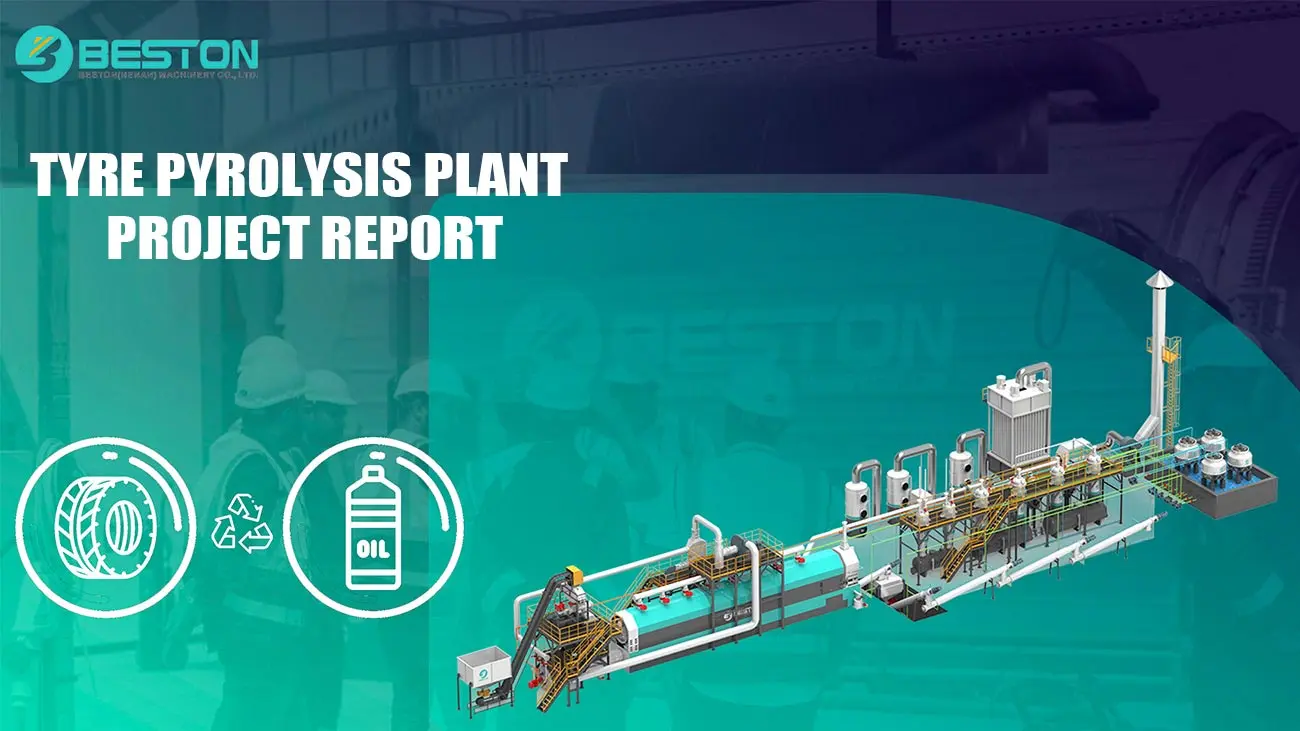

Pyrolysis technology has emerged as a sustainable and innovative solution for waste management and resource recovery. It offers an efficient method to convert waste materials like plastics, tires, and biomass into valuable byproducts such as oil, gas, and carbon black. If you are planning a pyrolysis project, understanding the different technologies available—whether you’re searching for a small pyrolysis machine for sale or exploring the capabilities of continuous pyrolysis equipment—is critical for success.

Pyrolysis Plant Project Report: Key Elements for Success

When planning to set up a pyrolysis plant, preparing a detailed pyrolysis plant project report is a crucial step in guiding your decision-making and securing financing. A well-structured report outlines the project’s goals, financial feasibility, environmental impact, and operational framework.

Key components of a pyrolysis project report include:

- Project Overview: Clearly define the scope of the project, including the type of waste to be processed (plastics, tires, etc.) and the expected output (oil, gas, carbon black).

- Market Analysis: Provide an in-depth analysis of market demand for pyrolysis products, as well as local regulations and environmental considerations.

- Technical Feasibility: Discuss the type of pyrolysis technology to be used, including whether you plan to install small pyrolysis machines or continuous pyrolysis equipment.

- Financial Projections: Include cost estimates for machinery, labor, energy, and maintenance. Calculate potential revenue streams based on oil, gas, and carbon black production.

- Environmental Impact: Detail the plant’s expected emissions, waste management strategies, and compliance with local environmental regulations.

- Operational Plan: Outline the plant’s operational structure, including the number of workers, shifts, and maintenance schedules.

Preparing a comprehensive pyrolysis plant project report ensures that you have a clear strategy for successful project implementation and can confidently present your plan to investors, partners, and regulatory bodies.

Small Pyrolysis Machine Perfect for Startups and Small-Scale Operations

For businesses or individuals looking to start on a smaller scale, investing in a small pyrolysis machine for sale is an ideal solution. These machines are designed to handle lower volumes of waste, making them suitable for startups, small recycling facilities, or companies with limited space and resources.

- Cost-effective: With lower upfront investment costs compared to large pyrolysis plants, small machines provide an affordable entry point for businesses looking to explore pyrolysis technology.

- Space-saving: These machines are compact and take up minimal space, making them easy to install and operate in small facilities.

- Scalability: While they handle smaller waste volumes, these machines offer the flexibility to scale up operations as your business grows.

- Energy Efficiency: Many small pyrolysis machines are designed with energy-efficient systems, reducing operational costs and environmental impact.

Applications for small pyrolysis machines include converting plastic waste, old tires, and even organic materials into valuable byproducts like pyrolysis oil, gas, and solid carbon residues. By investing in a small pyrolysis machine for sale, you can enter the waste management industry with a manageable budget while still contributing to sustainability goals.

Scaling Up for Large-Scale Waste Processing with Continuous Pyrolysis

For businesses looking to handle large quantities of waste on a continuous basis, continuous pyrolysis equipment is the best solution. Unlike batch systems, which process waste in discrete cycles, continuous pyrolysis systems allow for uninterrupted waste feeding and processing, maximizing efficiency and output.

- High Efficiency: Continuous systems can operate 24/7, allowing for large-scale processing of waste materials like plastics, tires, and biomass. This leads to higher production yields and more efficient use of time and resources.

- Automation: These machines are often fully automated, reducing the need for manual intervention and lowering labor costs.

- Energy Savings: Continuous pyrolysis equipment is designed to recycle energy within the system, using the heat produced during pyrolysis to power other parts of the process. This reduces energy consumption and operational costs.

- Environmental Compliance: Advanced filtration and emission control systems ensure that continuous pyrolysis plants meet strict environmental regulations, minimizing air pollution and harmful byproducts.

A large-scale pyrolysis plant equipped with continuous pyrolysis technology can convert tons of waste per day into valuable resources like pyrolysis oil, carbon black, and syngas. These byproducts have significant market value, offering profitable returns on investment.

Which Is Right for You Business?

When deciding between a small pyrolysis machine and continuous pyrolysis equipment, consider the following factors:

- Waste Volume: If you need to process small amounts of waste or are just starting in the industry, a small pyrolysis machine is a cost-effective option. For larger, industrial-scale operations, continuous pyrolysis equipment is the better choice.

- Investment Budget: Small pyrolysis machines require a lower upfront investment, making them suitable for startups or small businesses. Continuous systems are more expensive but offer higher returns in the long run due to their efficiency and capacity. More details in: https://bestonpyrolysisplant.com/

- Space and Resources: If space is limited, a small machine is ideal. However, if you have the resources and space to install a large plant, continuous pyrolysis equipment will yield greater output.

- Labor Requirements: Continuous pyrolysis systems are largely automated, reducing the need for extensive manual labor, while small systems may require more hands-on operation.