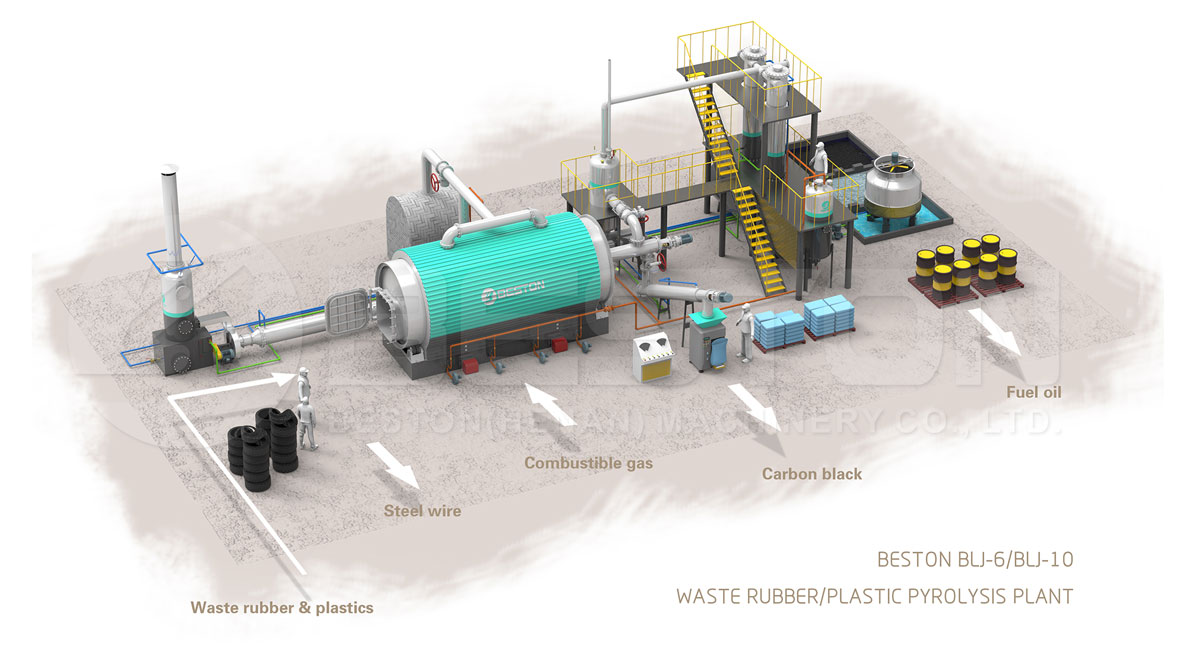

Are you shopping for a pyrolysis plant in the UK? If so, you have come to the right place. A pyrolysis plant helps transform waste rubber and scrap tires into valuable commodities such as pyrolysis oil, carbon black, and wire steel. A car tire takes up to 100 years to decompose in a landfill. Given the time taken by waste tires to decompose in landfills across the country, recycling such products with a pyrolysis plant will help save the environment while making a handsome profit in the process. If you are planning to start a tire recycling business in the UK, you should invest in a quality pyrolysis unit. Here are some tips to consider when investing in a pyrolysis plant in the United Kingdom.

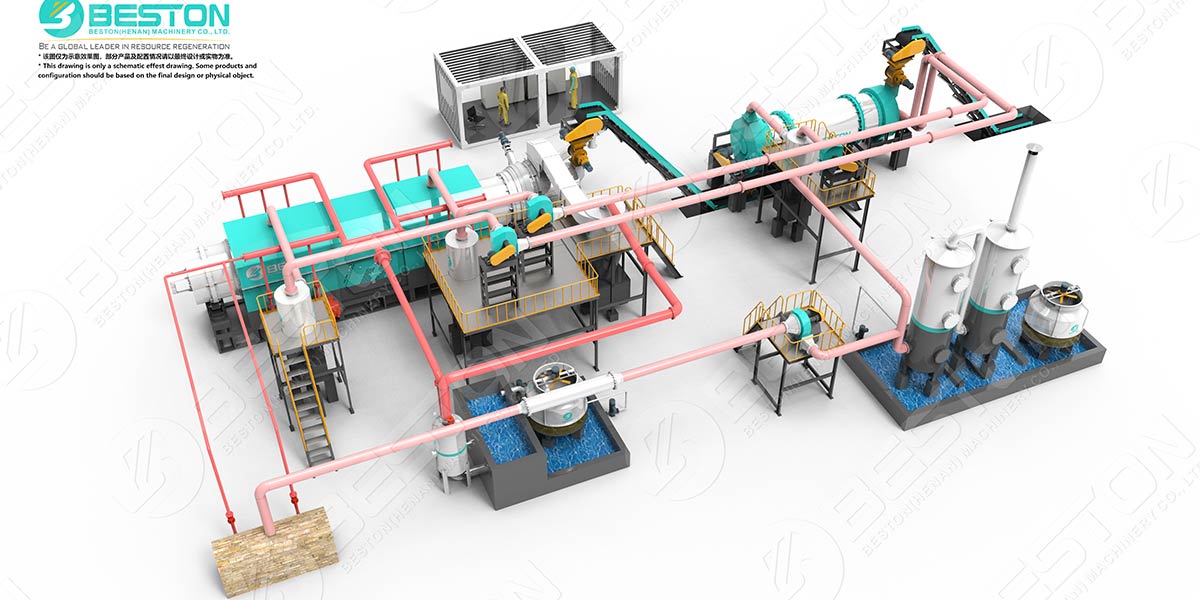

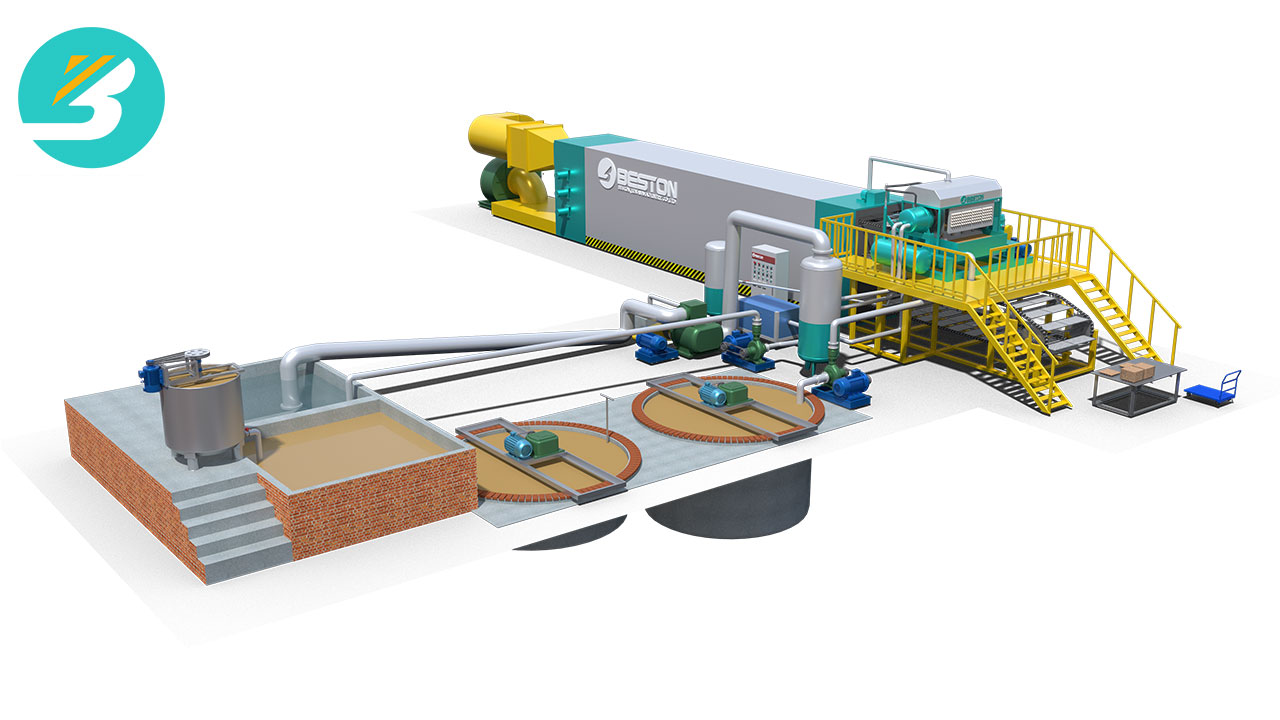

The pyrolysis process is a thermal decomposition process that transforms waste rubber products into profitable byproducts. The waste materials are entered into the sealed, oxygen-free reactor and heated to extreme temperatures up to 300 degrees Celcius. When the waste materials are heated to extreme temperatures inside the reactor, they produce vapor-containing oils of various viscosities. Water-cooled condensers are used to liquify the oils from vapor. The pyrolysis plant is 100% eco-friendly because there is no combustion or dioxin production during the process. The most important thing is to invest in a quality plant at an affordable pyrolysis machine price.

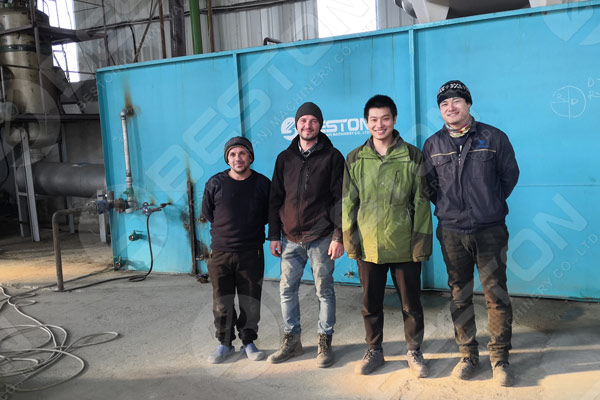

You can easily find tire pyrolysis plants across the country. There are hundreds of pyrolysis plant manufacturers in the UK. But all of these companies are not created alike. Your extensive research plays a crucial role in selecting the best pyrolysis plant manufacturer to invest in the machine. Buying a machine right from the manufacturer has its own advantages. You can find a manufacturer with excellent customer service and support and save money in the process. Aftersales service is not a problem when you buy directly from the manufacturer. When you have an issue with the machine, the manufacturer will help fix the problem without delay. The manufacturer should have been in the industry for many years and provide quality machines at affordable prices. You may ask more than one manufacturer to send their estimates from shopping for a pyrolysis plant in the UK. Please find suitable pyrolysis machines from Beston: https://bestonasia.com/pyrolysis-plant/continuous/.

Investing in a tire pyrolysis plant from Beston Machinery is a smart and expensive decision. You can earn extra money while saving the environment by making this decision. But you shouldn’t rush when buying a pyrolysis plant in the UK. Do your homework properly and research several manufacturers before you decide to invest in a quality product at an affordable price. That is the best way to buy a tire pyrolysis plant in the UK.