In the intricate world of oil drilling, the extraction process yields not only the coveted crude oil but also brings forth a challenging byproduct – drill cuttings. These cuttings, laden with hydrocarbons and potentially harmful substances, necessitate careful treatment before disposal to safeguard the environment. One of the advanced techniques employed for this purpose is thermal desorption. This comprehensive guide aims to unravel the intricacies of thermal desorption in processing oil drillings, exploring its principles, applications, advantages, and potential environmental implications. The thermal desorption equipment is useful.

Understanding Thermal Desorption

The Basics

Thermal desorption is a remediation technique that employs heat to separate and remove contaminants from solid matrices like soil or drill cuttings. In the context of oil drillings, the process primarily addresses the hydrocarbon-laden cuttings generated during drilling operations. These cuttings often contain residual oil, drilling mud, and other organic compounds that pose environmental risks if not treated appropriately.

The Process

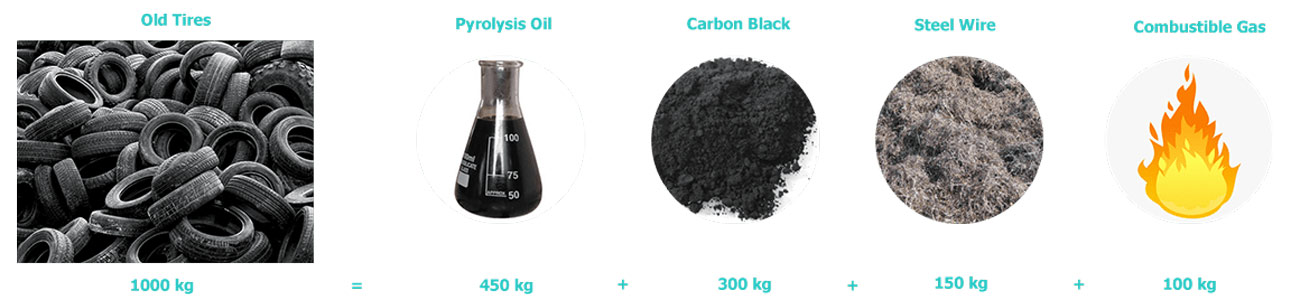

The thermal desorption process involves exposing the contaminated material to elevated temperatures in a controlled environment. The heat induces the release of contaminants, such as hydrocarbons, from the solid matrix. The volatile compounds evaporate and are then condensed or captured for further treatment or safe disposal. The remaining solids, now free of contaminants, can be returned to the environment or repurposed for other applications.

Equipment Used

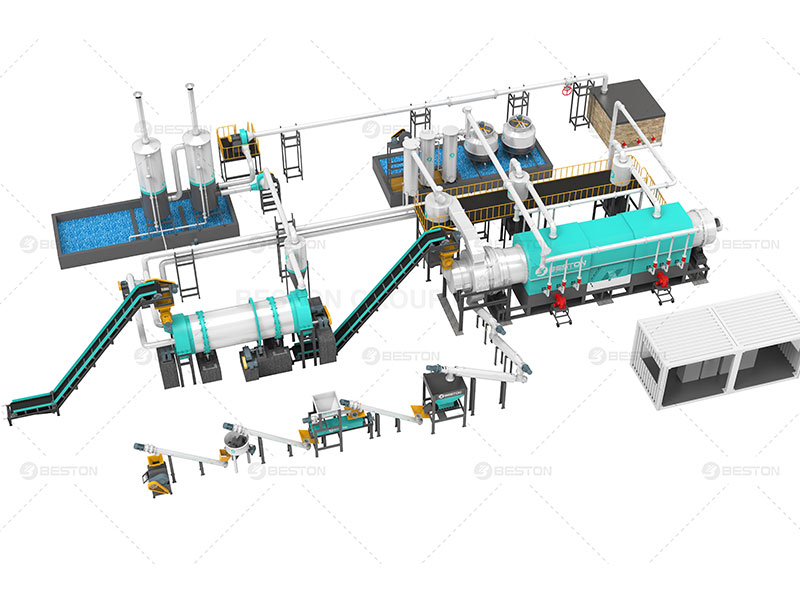

Thermal desorption units typically consist of a processing chamber, a heating system, and a collection system for vapors. Various types of thermal desorption equipment exist, including indirectly heated rotary kilns, direct-fired thermal desorption units, and thermal distillation units. The selection of equipment depends on factors such as the type and volume of waste, desired treatment efficiency, and project-specific requirements.

Applications of Thermal Desorption in Oil Drillings

Drill Cuttings Remediation

The primary application of thermal desorption in the oil and gas industry is the remediation of drill cuttings. As drilling progresses, cuttings become contaminated with drilling fluids and hydrocarbons. Thermal desorption efficiently separates these contaminants from the cuttings, allowing for the recovery of valuable resources and ensuring environmentally responsible disposal. View the oil sludge treatment system to process other waste.

Soil Remediation

Beyond drill cuttings, thermal desorption finds application in the remediation of oil-contaminated soils. Sites with historical oil spills or leaks can benefit from this technology, as it effectively removes hydrocarbons and other pollutants, restoring the soil to acceptable environmental standards.

Recovering Resources

Thermal desorption not only addresses environmental concerns but also offers an opportunity to recover valuable resources from the waste. The extracted hydrocarbons can be collected, treated, and potentially reused, contributing to the overall sustainability of oil drilling operations.

Advantages of Thermal Desorption

Efficient Contaminant Removal

Thermal desorption is highly effective in removing a wide range of contaminants from solid matrices. The process efficiently targets volatile and semi-volatile compounds, ensuring a thorough remediation of the contaminated material.

Resource Recovery

The ability to recover hydrocarbons from drill cuttings presents a significant economic advantage. Extracted oil can be refined and reintroduced into the production cycle, reducing the overall environmental impact and contributing to the sustainability of oil drilling operations.

Versatility

Thermal desorption is a versatile remediation technique suitable for various contaminants and matrices. It can be applied to different types of hydrocarbon-contaminated waste, making it adaptable to diverse environmental remediation challenges.

Reduced Environmental Impact

Compared to traditional disposal methods such as landfilling, thermal desorption significantly reduces the environmental impact of oil drilling waste. The process minimizes the need for land disposal and prevents the leaching of contaminants into the soil and groundwater.

Compliance with Environmental Regulations

Thermal desorption aligns with stringent environmental regulations governing the disposal of oil drilling waste. By effectively treating contaminated materials, operators can ensure compliance with local and international environmental standards.

Challenges and Considerations

Energy Consumption

The thermal desorption process requires substantial energy input to reach and maintain the elevated temperatures necessary for contaminant removal. While advancements in energy-efficient technologies have mitigated this concern to some extent, the energy requirements remain a consideration in the overall environmental impact of the process.

Cost Implications

The initial investment and operational costs associated with thermal desorption units can be significant. However, the economic feasibility of the technology often depends on factors such as the scale of the operation, the volume of waste to be treated, and the potential for resource recovery.

Residual Waste Management

While thermal desorption effectively removes contaminants from the solid matrix, the process may generate residual waste, such as ash or treated solids. Proper management and disposal of this residual waste are crucial to ensure that no new environmental concerns arise as a result of the remediation process.

Site-specific Considerations

The success of thermal desorption projects is highly dependent on site-specific conditions, including the type and composition of contaminants, soil characteristics, and local environmental regulations. Thorough site assessments and feasibility studies are essential to tailor the remediation approach to the unique challenges of each location.

Environmental Implications

Air Emissions

The thermal desorption process may release volatile organic compounds (VOCs) into the air, potentially contributing to air pollution. To mitigate this environmental impact, modern thermal desorption units are equipped with emission control systems such as condensers and scrubbers to capture and treat airborne contaminants.

Greenhouse Gas Emissions

The energy-intensive nature of thermal desorption can result in greenhouse gas emissions, primarily from the combustion of fuels for heating. The industry is continually exploring ways to optimize energy efficiency and explore alternative energy sources to minimize the carbon footprint of thermal desorption processes.

Ecological Impact

While thermal desorption is designed to address environmental concerns, the process itself may have ecological implications. Careful consideration of the surrounding ecosystem and adherence to best practices in site management are crucial to minimize any unintended impact on flora and fauna. The mobile pyrolysis unit processes small-scale waste.

Future Trends and Innovations

Advancements in Energy Efficiency

Ongoing research and development efforts are focused on enhancing the energy efficiency of thermal desorption processes. This includes the exploration of alternative heating sources, improved insulation materials, and the integration of renewable energy technologies to reduce overall energy consumption.

Integration of Smart Technologies

The adoption of smart technologies, such as sensor networks and real-time monitoring systems, is on the rise in thermal desorption units. These technologies enable operators to optimize process parameters, enhance control over the remediation process, and ensure compliance with environmental regulations.

Circular Economy Initiatives

The concept of a circular economy, where waste is minimized, and resources are efficiently utilized, is gaining traction in the oil and gas industry. Thermal desorption aligns with this approach by not only treating waste but also recovering valuable resources, contributing to a more sustainable and circular oil drilling process.

Conclusion

Thermal desorption stands as a sophisticated and effective solution in the oil and gas industry’s ongoing quest for environmentally responsible waste management. From remediating drill cuttings to recovering valuable resources, this process offers a multifaceted approach to addressing the challenges posed by hydrocarbon-contaminated waste. While challenges and environmental considerations persist, ongoing research and innovation hold the promise of further improving the efficiency and sustainability of thermal desorption in processing oil drillings. As the industry continues to evolve, the integration of advanced technologies and a commitment to responsible practices will shape the future of thermal desorption and its role in the broader landscape of oil and gas operations.